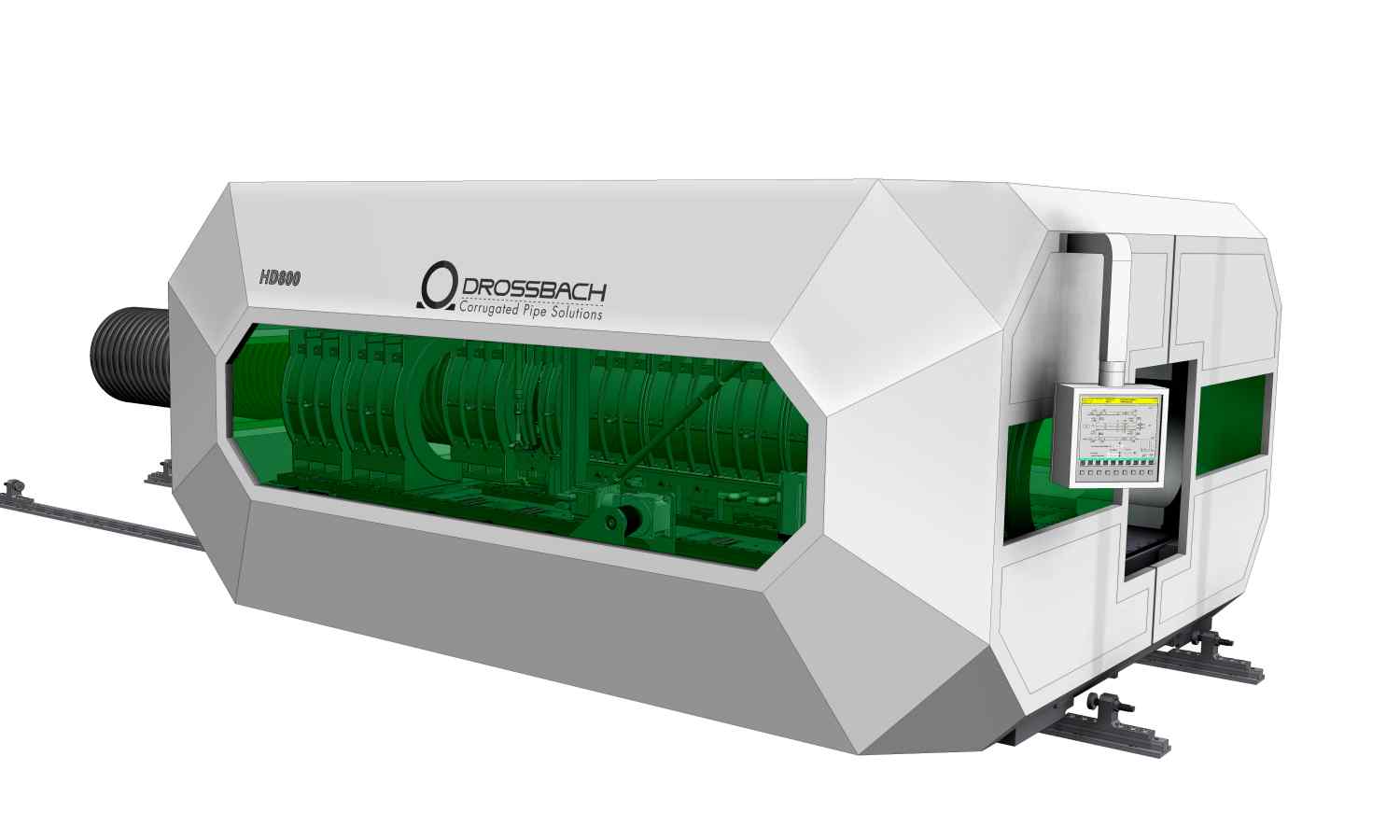

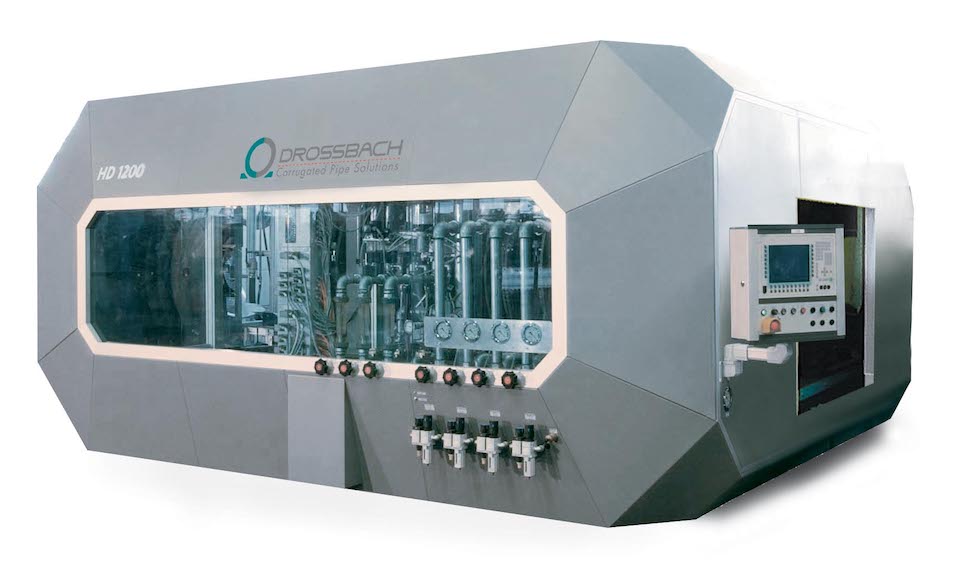

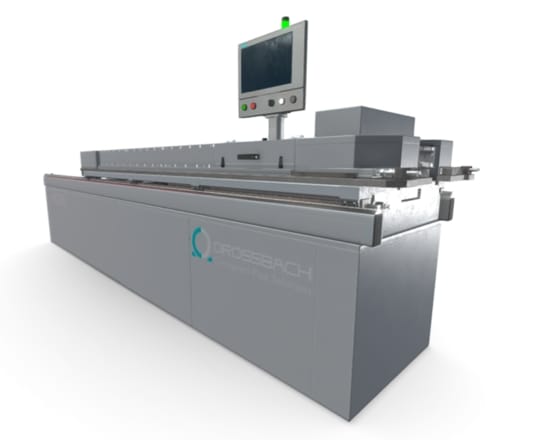

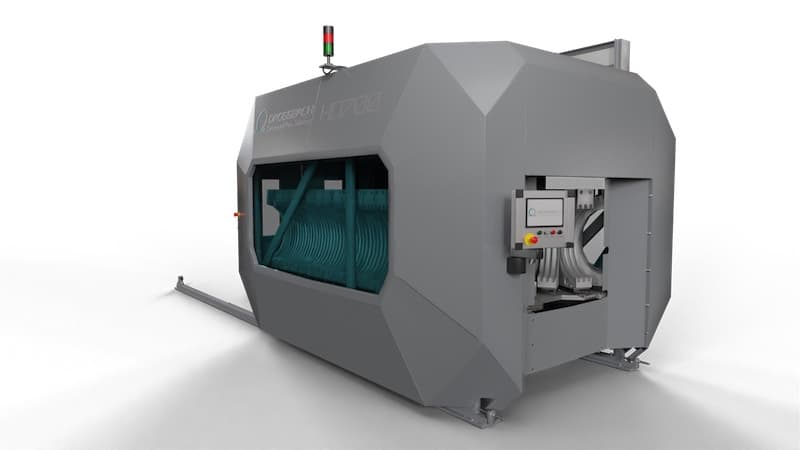

Drossbach HD 500-T3

Superior performance for medium sized diameters

Technical Data

| Max. mech. speed | 11 m/min / 36 ft./min |

| PE/PP output | 950 kg/h / 2.094 lbs/h |

| Measurements/weights: | |

| - Max. pipe outer diameter (OD) | 560 mm / 22" |

| - Min. pipe internal diameter (ID) | 100 mm / 4" |

| Number of mold blocks (per side) | 39 |

| Length | 5200 mm / 17.06 ft. |

| Width | 3070 mm / 10.07 ft. |

| Height (depending on extrusion height) | >3300 mm / 10.83 ft. |

| Length of molding area | 2060 mm / 6.76 ft. |

| Max. travel | 3850 mm / 12.63 ft. |

| weight of machine without mold blocks | 12400 kg / 27,337 lbs |

Characteristics

Documentation

3d-Modell

3d-Modell

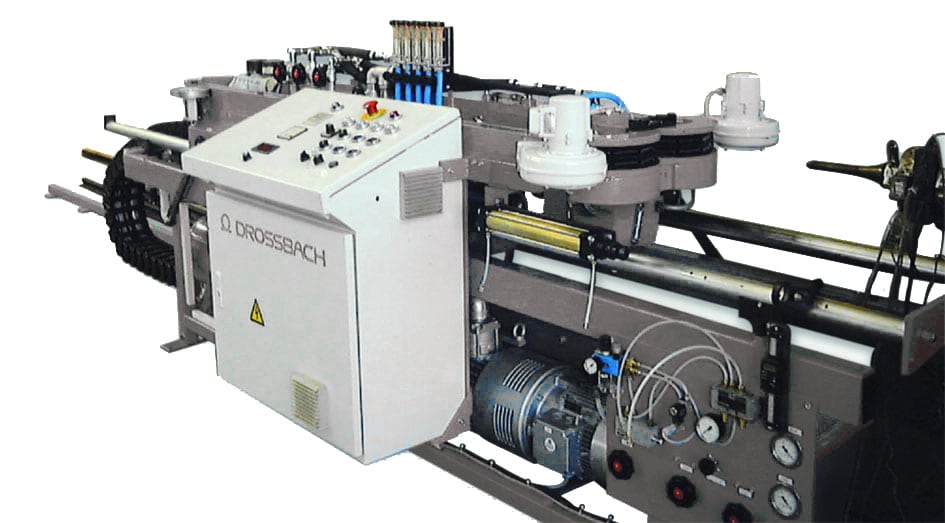

- Production of corrugated plastic pipes with high production speed thanks to directly water-cooled mold-blocks and an integrated full vacuum system.

- Corrugated pipe machine mounted onto a solid, welded frame. This guarantees stability during the production and is the basic for high speeds.

- Electrically driven side adjustment of the corrugator with position memory makes final tuning during production very simple and fast.

- Automatic vacuum control for perfect profiling of corrugated pipes. For each diameter and material of pipe the necessary vacuum level is stored in PLC memory and selected on the operator’s panel.

- Equipped with 39 directly water-cooled mold-block pairs for the production of pipes of 6 m /19.68 ft length, if required including inline produced sockets.

- Mould-blocks made of cast aluminum combine a low weight and excellent heat transfer.

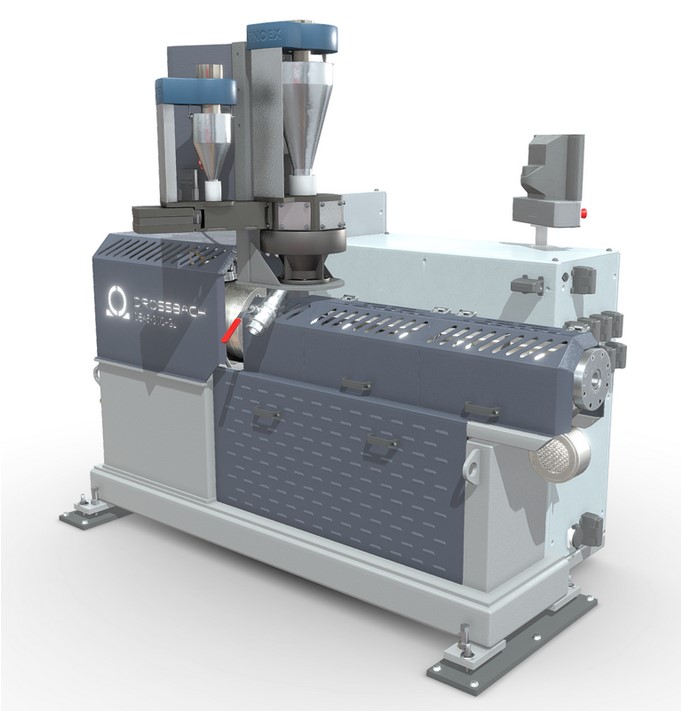

- The spiral-mandrel die head provides constant premium quality of the corrugated pipe with a consistent even wall distribution.

- After having adjusted, the die head is fixed to the corrugator by means of the centering ring, no further alignment necessary.

- Easy and convenient access to mould-blocks due to special doors on both sides of the corrugator and pneumatically openable roof allowing use of in-house crane for fast installation and removal procedures.

- Maintenance-free operation thanks to fully automatic centralized lubrication system.

- The corrugator is equipped with State of the Art drive system – no calibration needed during life time operations.

- Simple and fast exchange of mold block inserts.

- The complete diameter tools from ID 150 to ID 400 (6" - 16") are compatible with the HD 800 and the HD 1200.

DIAMETERS:

from ID 100 mm to OD 560 mm / 4" - 22"

Materials:

PE, PP, PVC, further plastics available upon request.

Application

Waste water

ID 100 - ID 500 / 4" - 20"

Drainage

ID 100 - ID 500 / 4" - 20"

Rain water

ID 100 - ID 500 / 4" - 20"

Tunnel-shaped drainage type C1

OD 100 - ID 350

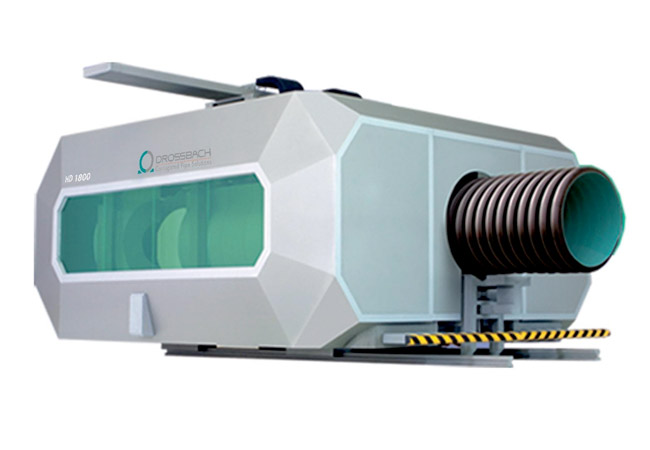

Corrugators

Other equipment in this category

Create an order request

+